Soybean Oil Production Line

For soybean oil production lines, our company can provide comprehensive services according to customer needs, including oil plant planning, engineering design, process flow, technology selection, equipment configuration and after-sales service, etc.

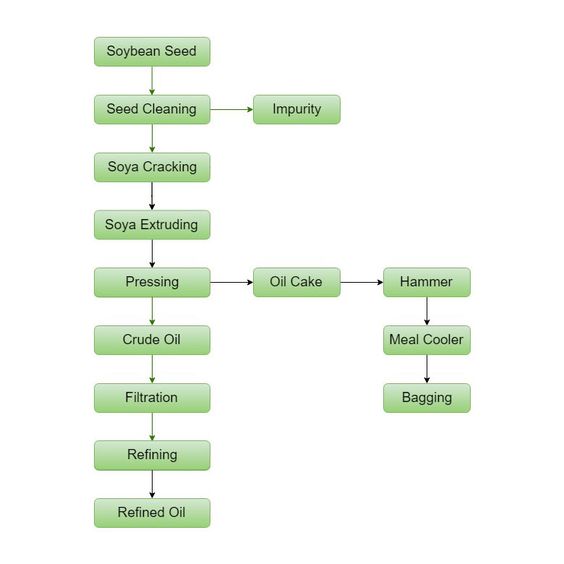

Workflow of soybean oil production line:

Soybean → Cleaning → Crushing → Softening → Flaking → Cooking → Pressing → Filtering

Soybean cleaning

Before oil is extracted, soybeans are first cleaned, dried and shelled. Soybean hulls need to be removed as they absorb oil and result in lower yields. This dehulling is accomplished by crushing the soybeans and mechanically separating the hulls and broken soybeans. Magnets are used to separate iron from soybeans. The soybeans are also heated to about 75°C, which coagulates the soy proteins, making it easier to extract the oil.

Extraction of soybean oil

The soybeans are first cut into thin slices, placed in a percolation extractor and immersed in a solvent (usually hexane). Countercurrent was used as the extraction system because it provides the highest yield. After removing the hexane, the extracted soy flakes contain only about 1% soybean oil and can be used as livestock meal or to produce foods such as soy protein. Separate hexane from soybean oil in an evaporator. The evaporated hexane is recovered and returned to the extraction process. The hexane-free crude soybean oil is then further purified.

Filtering of soybean oil

Crude soybean oil still contains many oil-insoluble and oil-soluble impurities that need to be removed. Oil-insoluble materials are removed by filtration, and soluble materials are removed by different processes, including degumming (removing phospholipids), alkaline refining (washing with alkaline solutions to remove free fatty acids, colorants, insolubles, and gums), and bleaching (using activated earth or Activated charcoal removes color and other impurities.

Soybean oil refining workshop process flow:

Crude soybean oil→ Continuous degumming and deacidification→ Continuous decolorization→ Continuous deacidification and deodorization→ Cooling – deodorized oil to dewaxing workshop

Soybean oil dewaxing workshop process:

Deodorized oil → Pre-cooling → Crystallization → Filtration and separation → Refined oil

Our technology

Advanced automation and intelligent control technology are used to monitor the entire production process to ensure product consistency and high efficiency of the production line.

he oil plants we build adopt environmentally friendly technologies with low energy consumption and low waste emissions, and comply with international environmental standards.

The process design fully integrates energy conservation and environmental protection, controls dust emissions, recovers heat energy, and reduces production energy consumption. The integration of processes and automation optimizes efficiency, reduces customer labor input, and improves product specifications and stability.

QI’E Machinery is China’s leading manufacturer focusing on edible oil processing solutions and equipment. We provide complete factory solutions for oilseed pretreatment, leaching, refining and deep processing. With more than 40 years of experience, we are committed to optimizing technical processes, engineering design, project management, installation and training to help customers build oil pressing plants around the world. When you are planning to build a vegetable oil processing plant, contact us today for a quote.