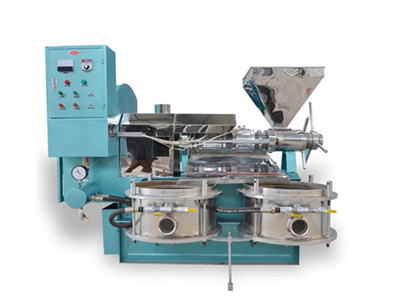

Commercial High Efficiency Peanut Oil Processing Machine

Peanut oil processing machine is used to extract peanut oil from peanuts. The complete set of peanut oil processing equipment consists of peanut oil pretreatment and pre-pressing machine, peanut oil solvent leaching device and peanut oil refining device. Our company is the best peanut oil machinery manufacturer and supplier in China, with extensive experience in designing and manufacturing various peanut oil processing machinery.

The peanut oil processing machine is clean in a single press, with a high oil yield and it saves labor and time. It can realize multi-stage propulsion in a single press, and the oil yield can increase by 10-30%. Compared with the old peanut oil processing machine, the normal oil yield can be 2 to 3 percentage points higher. It can process 50kg peanuts on average, and the oil yield increases 1~3kg oil more. The annual economic benefits are very considerable.

Application of peanut oil processing machine:

The peanut oil processing machinery designed by our factory is an advanced edible oil processing machinery with the characteristics of high oil yield, good quality, simple design, easy use, and continuous operation.

Peanut oil processing machine can be used for a variety of raw materials such as black beans, peanuts, baobab seeds, soybeans, castor seeds, rapeseed, palm kernels, cotton seeds, shea butter, sesame seeds, pine nuts, flax seeds, sunflower seeds, dried coconut, mustard seeds wait.

Next, we will introduce the entire peanut oil processing process and how to extract peanut oil from peanuts step by step

The peanut oil pretreatment and pre-pressing section is the basic part of peanut oil processing equipment. This section includes: cleaning, crushing, softening, flaking, baking and other processes to adjust the peanut seeds to the best oil extraction state to facilitate squeezing out oil. It will facilitate the next step of peanut oil production section.

Specification

| Model | Capacity | Power(kw) | Size | Weight(kg) |

| 6YL-68 oil press machine | 50kg/h | 5.5 | 920*480*760 | 140 |

| 6YL-80 oil press machine | 100kg/h | 5.5 | 1320*540*1020 | 330 |

| 6YL-95 oil press machine | 150-200kg/h | 7.5 | 1940*700*780 | 550 |

| 6YL-100 oil press machine | 200kg/h | 7.5 | 1700*600*1130 | 480 |

| 6YL-120 oil press machine | 250kg/h | 11 | 1650*630*1260 | 680 |

| 6YL-160/zx130 oil press machine | 10-12T/24H | 15 | 2050*820*1400 | 820 |

| 6YL-180/ZX160 oil press machine | 13-18T/24H | 18.5 | 2020*680*1460 | 980 |

Characteristics of Our peanut oil processing machine

1. Healthy!

Physical squeezing craft maximally keeps the nutrients such as the protein, fatty acids and minerals, etc.

2. High working efficiency!

The spiral squeezing structure can achieve high oil output, thus the oil content of the residue cake is low.

3. Long durability!

All the parts are made of the most suitable material and treated with refined crafts to ensure the long term runing, such as cemented quenching and tempering to increase the hardness, consequently the durability.

4. Cost-effective!

The wearing parts on the machine such as the squeeze loop, squeeze spiral and squeeze bar are designed to be dismountable. When they are out of service period, users only need to replace them and no need to displace the whole machine.

As an expert in edible oil processing equipment and complete edible oil production lines, our company is a reliable choice for your peanut oil processing business. We can supply small, small, medium and large industrial scale peanut oil plant. We have established a comprehensive business model that includes turnkey vegetable oil processing solutions, equipment manufacturing, factory installation and commissioning, technical training and all-round after-sales service. If you plan to build a peanut oil processing plant, please feel free to tell us your oil making needs!

Our factory

1. More than 40 years of oil press manufacturing experience.

2. 7 oil press technology patents.

3. Fully inspected before shipment, with a quality pass rate of over 98%.

4. More than 400 professional and technical personnel. 10% of them are mechanical engineer technicians.

5. Widely used in our lives and exported to more than 100 countries.