Sesame Oil Production Line

The sesame oil production line is improved by combining a modern hydraulic oil pressing workshop with traditional baking, dust removal and cooling methods. In the sesame oil manufacturing process, combining modern assembly line production with traditional frying equipment can improve production efficiency while retaining the traditional flavor. The superior oil production line not only retains the influence of baking and dust removal on the aroma of sesame oil in traditional processes, but also reduces the time and space occupied by traditional processes such as grinding, stirring, and oil oscillation separation. Moreover, the improved oil pressing production line also has the characteristics of modern hydraulic press technology, such as high mechanical automation and high production efficiency.

In the sesame oil production line, seed cleaning equipment is first used to pretreat and clean sesame seeds to remove impurities, and then the clarified seeds are pressed through professional seed processing machinery to obtain crude sesame oil. However, these oils must be solvent extracted and then refined to obtain pure edible oils. If necessary, it is best to install a filling machine to fill and package the oil.

Steps of Sesame Oil Production Line

1. Sesame Cleaning:

Once the sesame seeds are delivered to the factory, they are cleaned using seed cleaning equipment to remove unwanted products. Cleaning seeds helps to select good seeds and clean them to remove dust, foreign matter and stones. Cleaning machine is an essential machine in sesame oil production.

2. Sesame Seed Dry Roasting:

Sesame seeds are roasted and dried. They are then cooked and ready for crushing. The washed seeds are heated to remove excess moisture. Sesame dry frying machine is an important equipment in sesame oil production.

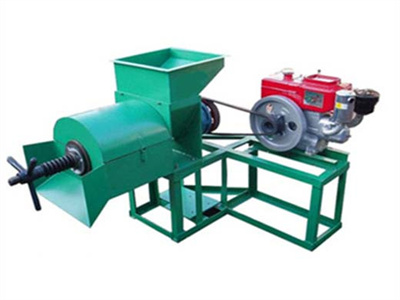

3. Sesame Pressing Process:

Once the seeds are completely dry, they can be pressed or pressed using a sesame oil press. After the oil is pressed from the seeds, it takes a while for the oil to settle.

4. Filter Crude Sesame Oil:

After the oil settles after pressing, some oil cake mixed with the oil will appear. Straining is done to separate the seeds from the oil. This will make it easier for the refining layer to extract the final oil.

5. Sesame Oil Refining:

After filtering, it does not mean that the oil is ready for packaging. The oil is filtered one last time before packaging. Filtration ensures that the oil is completely pure and free of any oil cake. Once the oil has settled and been filtered, it is ready for packaging.

6. Sesame Oil Packaging:

Once the oils go through all of these processes, they are packaged into barrels or cans via specialized oil filling lines, ready for sale in the market. They are also transported to other companies that use the oil to produce other products.

Advantages of Improved Sesame Oil Production Line

1. Our improved oil pressing process adopts high and low temperature combined roasting method, which can minimize the loss of protein content and other nutrients (such as vitamin B and linoleic acid) in sesame seeds. At the same time, the oil production rate is increased and production costs are reduced. The structure of edible oil in our country has been improved, and it can not only be used for seasoning, but also for cooking and eating.

2. The oil production rate of modern pressing workshops is 2 to 3 percentage points higher than the traditional oil production rate. And it saves labor: for small grease manufacturing, 1 to 2 people can organize the entire pressing workshop.

Sesame oil press machine is suitable to extract oil from oil seeds like white and black sesame, corn germ,soybean ,peanut ,cottonseed,rapeseed,sunflower and other oilseeds. Sesame oil production machine is multi-functional edible oil processing equipment which is popular in many countries and and regions.