Peanut Oil Production Line

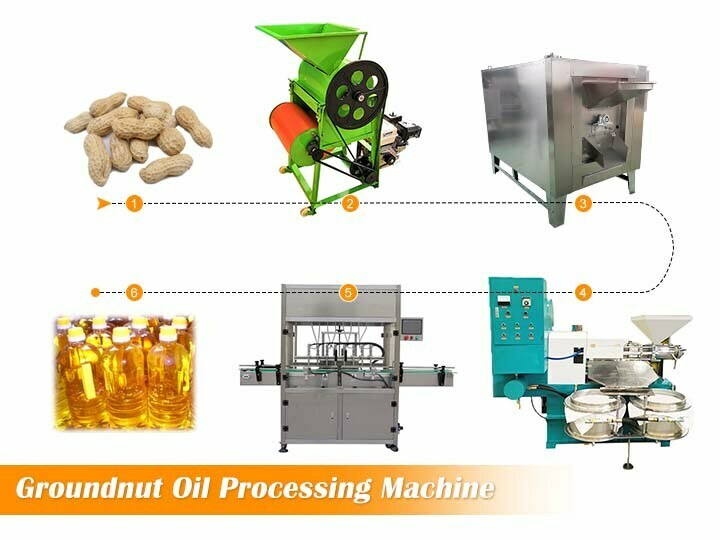

Peanut pretreatment process:

Peanuts must first be pre-treated by professional seed cleaning equipment. The cleaned peanut seeds are then sent to the oil pressing plant, where they are pressed into oil by the oil press. However, crude peanut oil often contains many impurities.Therefore, for edible oil, the pressed peanut oil needs to be extracted in an oil pressing plant, and then the pressed oil is sent to a refinery for further processing.

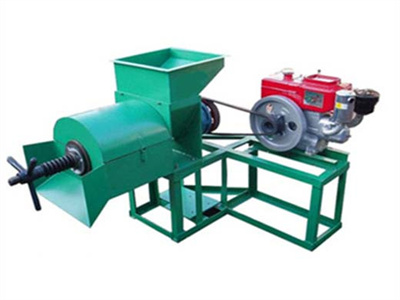

Peanut oil pressing process:

Pressed peanut oil is made by pressing, and extracted peanut oil is made by solvent extraction.Due to the high residual oil rate during the pressing process, the residual oil content is about 6%-8%. Large oil mills usually use pre-pressing and leaching processes to produce peanut oil.The pre-pressing and leaching process is to first press most of the oil, and then perform solvent leaching of the peanut cake to further extract the remaining oil in the oil cake and increase the oil yield rate.

Peanut cake solvent extraction process:

Solvent leaching equipment can reduce the residual oil in the cake to less than 1%, improve the quality of the cake, and better retain proteins and other substances in the cake.

Peanut crude oil refining process:

Peanut crude oil is processed by refining equipment to remove colloids, free fatty acids, moisture, pigments, odors, waxes, solvent residues and other impurities in the oil to ensure the safety of edible oil and improve the quality of finished oil.

Features of peanut oil processing plant

1.The peanut oil production line has a wide range of options. Therefore, it can meet the production needs of different large, medium, and small peanut oil production institutions. Customers can choose the production line with the right output according to their own production output. Besides, you can also choose several machines instead of the entire peanut oil production line.

2.Wide application. Apart from peanuts, peanut oil press machine can press rapeseed, sunflower seed, and other raw materials.

3.High oil production efficiency and oil yield. The oil press adopts multi-stage propulsion squeezing. with an automatic temperature control function, you can set different temperatures for different oil materials. With the smart oil press, the peanut oil production line’s oil output rate is greatly improved.

4.The main components are made of high-quality steel, through advanced heat treatment technology such as carburizing. The service life of the equipment is more than 10 years.

How to choose a suitable peanut oil production plant?

In order to meet the needs of different customers, we as an oil press manufacturer, produce machines of various models and outputs. Therefore, many machines in peanut oil production lines usually have multiple models. How to choose a peanut oil processing line depends on the size of your business and expected output.

Service

We provide project consulting and feasibility analysis. Help clients evaluate the economic benefits and market potential of projects.

We provide engineering design and project management services to ensure projects are completed on schedule and within budget.

We provide installation, commissioning and employee training to ensure that our customers’ employees can effectively operate the production line and understand the necessary maintenance knowledge.

We provide after-sales service and technical support, including but not limited to regular maintenance, troubleshooting and technical upgrades.

We provide comprehensive support to customers in building peanut oil production lines. From project planning to every stage of production line operation, we ensure that customers can achieve efficient, stable, and sustainable production operations. Through continuous technological innovation and optimized services, our goal is to help customers increase production capacity, reduce costs, and improve the market competitiveness of final products.