Cottonseed oil is oil extracted from cottonseed. The common extraction method is physical pressing of cottonseed. The pressed cottonseed oil is called crude cottonseed oil. The byproduct obtained after oil pressing is cottonseed oil cake/residue. After refining, the finished edible cottonseed oil is obtained. The color of cottonseed oil is darker than other oils. After refining, cottonseed oil removes toxic substances such as cottonphenol and can be consumed by the human body. It contains a large amount of essential fatty acids. Since the content of linoleic acid in cottonseed oil is particularly high, it can effectively inhibit the rise of cholesterol in the blood and maintain human health. The absorption rate of cottonseed oil by the human body is 98%.

A Cottonseed oil expeller is a machine designed to extract oil from cotton seeds using mechanical pressure. Operating with mechanical efficiency, it ensures a thorough extraction process without the use of heat or chemicals. The resulting cotton seed oil maintains its natural properties, making it suitable for various applications. Cotton Seed Oil Expellers are essential in the cottonseed oil industry, contributing to the production of edible oils, industrial products, and other derivatives from cotton seeds.

Standard Technical Parameters

| MODEL | CAPACITY (T/D) | POWER (KW) | DIMENSIONS (MM) | OIL RESIDUE (%) | SHAFT SPEED (RPM) | WEIGHT (KG) |

| 6YL-100 | 4-6 | 11 | 1700*600*1300 | ≤7 | 30-40 | 460 |

| 6YL-105 | 5-7 | 11 | 1850*650*1400 | ≤7 | 45-55 | 560 |

| 6YL-120 | 6-8 | 15 | 1850*650*1400 | ≤7 | 45-55 | 560 |

| 6YL-130 | 8-10 | 18.5 | 2150*700*1500 | ≤7 | 35-39 | 730 |

| 6YL130-9A | 10-12 | 18.5 | 2150*700*1500 | ≤7 | 35-39 | 780 |

| 6YL-140 | 12-14 | 22 | 2200*700*1500 | ≤7 | 35-39 | 850 |

| 6YL-160 | 18-20 | 30 | 2250*750*1500 | ≤7 | 35-39 | 980 |

Main Features:

Compared with other manufacturers, our products have the following main advantages:

1. High efficiency! The residual oil in cake residue is less than 7.8%

2. Low cost! Compared with competitors, our machines are more affordable

3. Easy to operate! Our machines are easy to operate, and we also provide detailed Chinese and English operation manuals for your reference.

4. Long durability! The extrusion ring and extrusion spiral are heat treated such as carburizing and quenching. The service life of our machines is more than 10 years, in addition, we produce almost all machine parts in our own factory, so the wearing parts and spare parts are available all year round to solve your after-sales service problems.

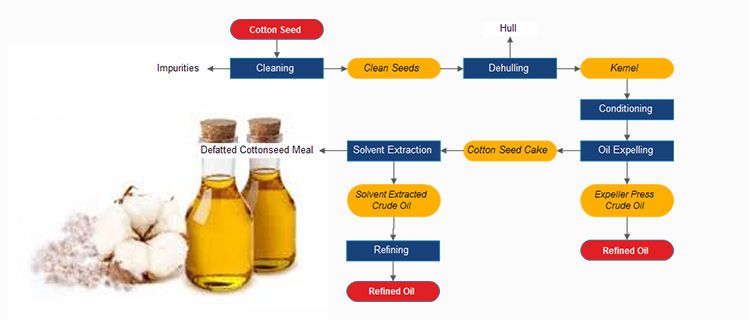

The complete cottonseed oil processing plant has a series of process, including delintering, dehusking, oil pressing, solvent extraction for oil, oil refining and more. Now, it has been a popular for many investors or oil millers to start or expand their edible oil manufacturing business by setting up cotton seed oil processing plant. But, you may have a lot of questions about how to establish your own oil mill plant to process cotton seeds, among which cottonseed oil production process, cottonseed oil mill machinery and price, and complete cotton seed oil processing plant setup cost are the most important and relatively complicated. Fortunately, you are at the right place to get answers of all of these questions.

FAQ

1. Delivery time.

—20~30 days after order confirmation. We need time to prepare machine according to exporting standard, wear-in, making wooden box, fumigation and suitable ship arrangement from forwarder.

2. If I don’t know how to operate this machine? how can I do?

—-Our machine has been tested OK and fully assembled before shipping, customer just needs to make2~4 hours wear-in and then can work.

3. What’s wear-in for new machine?

—- use 10 KG oil cake + 1KG sand + 1KG water, mix them, put in oil press, wear in 3~4hs.

1st hour, adjust oil cake thickness as 3mm.

2nd hour, adjust oil cake thickness as 2.5mm.

3rd hour, adjust oil cake thickness as mm.

4. What are cold press and hot press?

—-Cold press is pressing dry and raw seeds. Usually need to press 2 times to get maximum oil.

—-Hot press is pressing roasted seeds. Usually only press 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture. (We produce seeds roaster heated by economical fuel.