Canola Oil Production Line

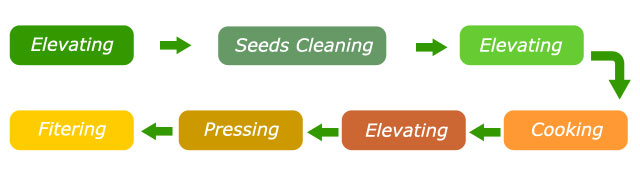

Canola, the seed used to make rapeseed oil, has grown in popularity over the years, becoming the second largest oil-producing crop. Therefore, the demand for rapeseed and its oil is increasing, making rapeseed oil production a very profitable business. The main suppliers of canola oil around the world are Canada, India, China, Europe and Australia. Even in other sectors, it is becoming increasingly common for potential entrepreneurs to enter the rapeseed oil industry. For those who are interested, let’s take a look at how rapeseed oil is made. Of course, the first thing you need is a lot of canola. You will then need to purchase some heavy machinery. The machinery consists of cleaning equipment, cookers, presses and refiners.

Since the establishment of the company, we have been focusing on canola oil extraction equipment. We can provide turnkey services for a canola oil production line. For special production capacity, our engineers can help you design and install canola oil extraction equipment according to your actual situation.

Key components delivered for canola oil production line equipment include:

1. Pressing: winnowing screen, electric heating drum baking machine, screw conveyor, screw canola oil pressing equipment, plate and frame filter;

2. Refining: rapeseed oil refining equipment, circulating water tank, decolorizing oil tank, vacuum oil filter;

3. Filling: refined oil storage tanks, oil pumps, filling machines, capping machines, compressed air storage tanks.

The cleaning equipment and pre-treatment equipment in the pressing workshop ensure the high output and high quality of oil products to the greatest extent. The plate and frame filter removes residual impurities and maintains oil purity; the circulating water tank in the refinery workshop can adjust the temperature during the refining process and promote efficient cooling. We use frames and pipes made of high-quality materials to ensure that the canola oil flows seamlessly, is durable, and is not easily damaged; the equipment in the filling workshop simplifies the packaging and storage process, making it efficient while maintaining the freshness of the finished oil.

Features of Canola Oil Production Line

1.Wide application for various seeds and nuts

2.Small investment, fewer land space, fewer labor but with the complete function of the production.

3.Easy to operate, install and commissioning.

4.The semi-continuous can avoid the unstable material feeding caused by manual and can make the worker safety more under the higher temperature working situation.

We can offer turnkey service of canola oil production line including design, installation, trail run, etc. Our professional engineers can help you design and install canola oil extraction plant according to your capacity and requirements. If you want to know more about canola oil production line, please feel free to contact us.